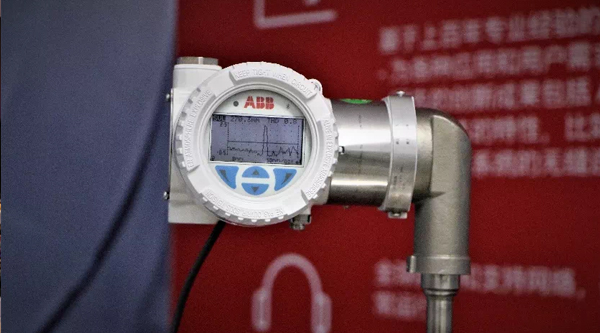

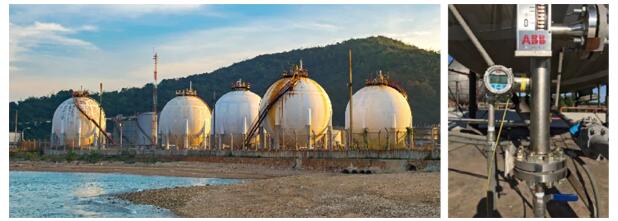

Recently, based on 25 years of magnetostrictive design and operation experience, ABB’s global R & D team of measurement and analysis business has made a breakthrough upgrade to the product, bringing the measurement experience of magnetostrictive liquid level gauge to a new height. ABB magnetostrictive liquid level gauge integrates backlight, Bluetooth, touch control and waveform display to achieve up to 2G vibration resistance and provide additional sealing solutions.

Innovation and upgrading for the future

ABB’s new generation magnetostrictive liquid level gauge has innovatively improved the software and hardware structure of the product, greatly improved the anti-interference ability and the stability of large range measurement, and comprehensively upgraded the operation and control requirements of customers on the basis of summarizing the complex working condition requirements of customers over the years:

Smart HMI has Bluetooth and backlight functions, and can touch or remote data transmission without opening the cover, so as to prepare for the advent of the era of intelligent sensors;

Recently, based on 25 years of magnetostrictive design and operation experience, ABB’s global R & D team of measurement and analysis business has made a breakthrough upgrade to the product, bringing the measurement experience of magnetostrictive liquid level gauge to a new height. ABB magnetostrictive liquid level gauge integrates backlight, Bluetooth, touch control and waveform display to achieve up to 2G vibration resistance and provide additional sealing solutions.

Innovation and upgrading for the future

ABB’s new generation magnetostrictive liquid level gauge has innovatively improved the software and hardware structure of the product, greatly improved the anti-interference ability and the stability of large range measurement, and comprehensively upgraded the operation and control requirements of customers on the basis of summarizing the complex working condition requirements of customers over the years:

Smart HMI has Bluetooth and backlight functions, and can touch or remote data transmission without opening the cover, so as to prepare for the advent of the era of intelligent sensors

Basic principle and structure of ABB magnetostrictive liquid level gauge

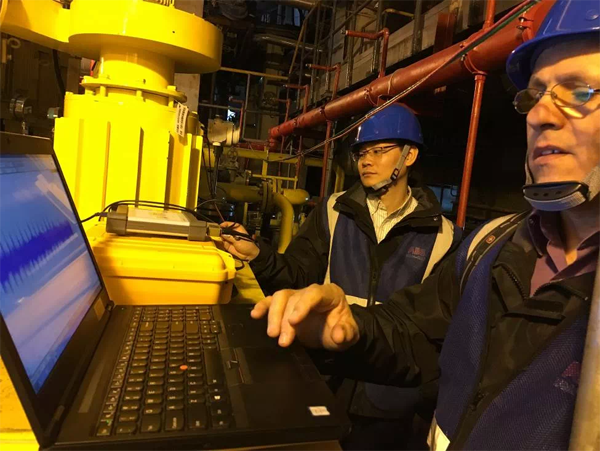

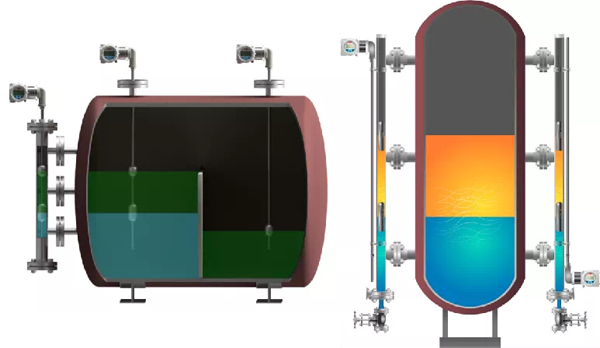

Magnetostrictive level gauge based on the principle of vibration wave acquisition under the excitation of magnetic floating ball, has unique technical advantages compared with traditional radar, ultrasonic and other liquid level products under complicated conditions such as high temperature, strong corrosion, steam, foam, emulsified layer and liquid interface. Weak vibration wave collection requires sensitive and reliable sensors and software and hardware algorithms to deal with various interference sources. Technical breakthrough and long-term function polishing are essential.

2. With the fixed cycle current pulse excitation, a magnetic field is induced around the magnetostrictive line in the probe rod.

3. The induced magnetic field interacts with the magnetic field of the magnetic float to produce torsional stress wave. The torsional stress wave propagates from the position of the magnetic float to both ends of the magnetostrictive line at a known speed.

4. The patented sensing element used in the transmitter component converts the received mechanical torsion into an electronic return pulse.

5. The microprocessor-based electronic device measures the elapsed time (flight time) between the start pulse and the return pulse and converts it into a position measurement proportional to the float level.

ABB’s new generation magnetostrictive LMT series products have achieved leapfrog upgrading on the basis of the classic generation magnetostrictive product K-TEK at100 / 200, so that the product stability and use experience have reached a new height, especially the response ability to severe working conditions has been greatly improved. ABB magnetostrictive liquid level gauge has entered the era of 2.0.

Post time: Dec-17-2021