Visual inspection

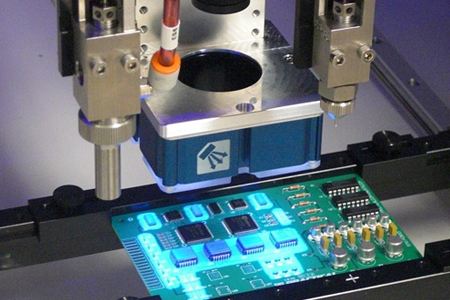

With the development of industrial automation, the application scope of machine vision is gradually expanded and improved. The application of machine vision is mainly reflected in the semiconductor and electronic industries. Due to the size of components and the high specification of packaging technology, it is difficult for human eyes to find subtle defects. In addition, the detection technology with large amount of detection, intelligence and high precision has become a need. In China, visual inspection is mainly used in the packaging and finished product inspection links of 3C manufacturing, automobile industry, food processing, pharmaceutical production and sheet metal industry, including pictures, colors and characters. With high-pixel industrial camera and high-performance Android all-in-one machine, it can complete the image collection and processing of the detected objects and complete the inspection tasks.

As an important part of the visual inspection system, Android all-in-one machine should meet a variety of needs, be able to deeply learn algorithms, establish model libraries, and deal with various inspection needs, including color difference, irregularity, defects, etc; It should not only meet the needs of the external environment of the detection work, but also show excellent performance in the aspects of detection software compatibility, program input and output, data processing and feedback; It can ensure the same high accuracy of moving object detection as static object detection; In case of defects, they can call the police in time.

Visual inspection system

Visual inspection is an application of machine vision technology. Its development and application are closely related to machine learning. Extensive popularization and application can make up for the deficiency of manual detection, further expand the depth and breadth of visual detection, ensure the detection accuracy, greatly improve the product detection speed, effectively reduce the labor cost and increase the delivery speed of goods. The application advantages of touch five generation Android all-in-one machine in visual inspection system are mainly reflected in performance and adaptability. Military grade attributes can cope with harsh environment, meet the in-depth learning of different algorithms, and meet the inspection needs of a variety of different products. It has wide applicability and high cost performance.

Visual inspection consists of multiple links. The detection involves the cooperation of multiple technologies to achieve accurate detection without omission. The complete detection system still needs the coordination of illumination, industrial camera and detection software. The application of touch intelligent Android all-in-one machine in visual inspection central control terminal can give play to its advantages in intelligent intelligent control hardware structure, adaptability to software, environmental adaptation, stability and so on.

Post time: Dec-20-2021